Air Header

Products

- Fittings

- Instrumentation Valves

- Manifold Valves

- Double Block And Bleed Valves

- Industrial Valves

- Quick Release Couplings

- Air Headers

- Condensate Pots

- Flanges

- Flange To Tube Adaptors

- Thermowells

- Fastners

- Pipe Clamps

- Flush Rings

- Hose Fittings

- Heat Exchanger Tube Plugs

- Heat Exchanger Ferrule Inserts

- Vent Plugs

- Header Unf Plugs

- Grease Fittings

- Pipes And Tubes

- Coils, Sheets & Plates

- Angle, Channels & Bars

- Tube Sheets

- Heavy Machined Components

-

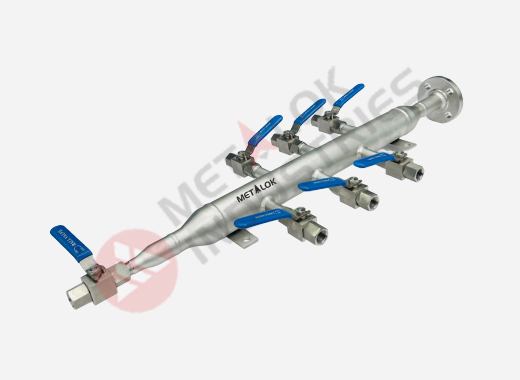

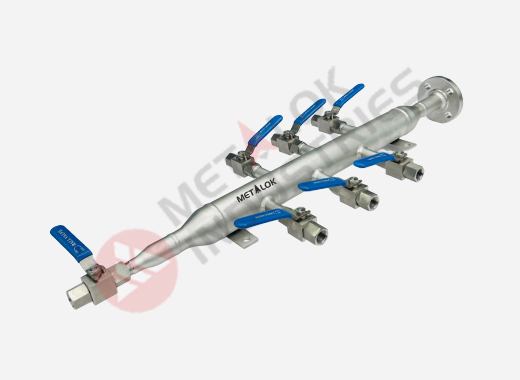

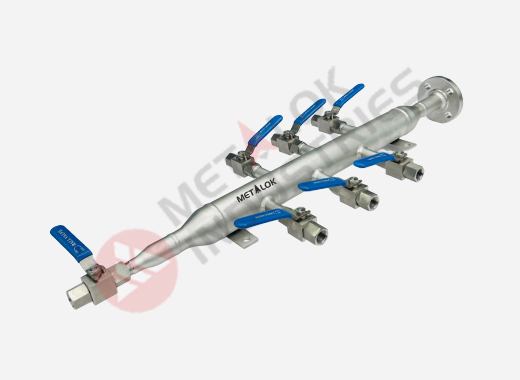

6 Way Air Header

6 Way Air Header

are precision-engineered components designed for secure, leak-proof connections in instrumentation and process tubing systems across the chemical, oil & gas, and power industries. These fittings offer reliable leak-tight sealing through a dual ferrule mechanism, ensuring consistent performance under high-pressure conditions up to 11,000 psig. Built from a range of corrosion-resistant materials like stainless steel, brass, Monel, and Inconel, they perform exceptionally in aggressive and high-temperature environments. The versatile design accommodates a wide variety of tubing sizes (1/16” to 2” and 2 mm to 50 mm), with multiple end connection options. Featuring a low torque, easy-to-install design, our fittings allow for effortless assembly, reassembly, and precise alignment—delivering long-term reliability and reduced maintenance costs.

- Centralized Air Distribution

Simplifies the system by providing multiple air take-off points from one header. - Space-Saving Design

Reduces pipe clutter and optimizes layout in compact installation areas. - Leak-Proof Operation

Ensures tight, reliable connections with minimal air loss for energy efficiency. - Reduced Installation Time

Minimizes individual piping runs, saving time and labor costs. - Customizable Configurations

Tailored outlet numbers, sizes, and valve types to meet specific system requirements.

- Multiple Outlet Ports

Available with 2 to 20 outlets; threaded (NPT/BSP) or flanged connections. - High-Quality Construction

Manufactured from SS304, SS316, Carbon Steel, or custom alloys for durability and corrosion resistance. - Mounting Flexibility

Comes with brackets or clamps for wall, panel, or skid installation. - Integrated Drain Valves

Optional drain valve provided for removing condensation and maintaining line purity. - Pressure & Temperature Rated

Designed to withstand pressures up to 6000 PSI and temperatures suitable for industrial environments.

Air Header Products

- 6 Way Air Header