Call Us

Manifold Valve

A manifold valve is a compact, multi-port valve system designed to control, isolate, and regulate fluid or gas flow in instrumentation and process systems. It integrates multiple valves into a single unit, reducing the need for separate fittings and minimizing potential leakage points. Commonly used in pressure measurement, hydraulic, and process control applications, manifold valves provide efficient operation, space savings, and enhanced system reliability.

Advantages of Manifold Valves:

- Compact Design – Combines multiple valves in a single unit, saving space and reducing installation complexity.

Leak-Free Performance – Fewer connection points minimize the risk of leaks, improving system efficiency.

Easy Operation – Allows quick isolation, calibration, and maintenance of instruments.

High Pressure & Temperature Resistance – Designed to handle extreme operating conditions.

Durability & Longevity – Made from corrosion-resistant materials like stainless steel for extended service life.

Improved Safety – Reduces the risk of leaks and pressure fluctuations in critical applications.

Versatile Applications – Used in oil & gas, chemical processing, power plants, and instrumentation systems.

Cost-Effective Solution – Reduces piping and fitting costs while enhancing overall system efficiency.

Our Products

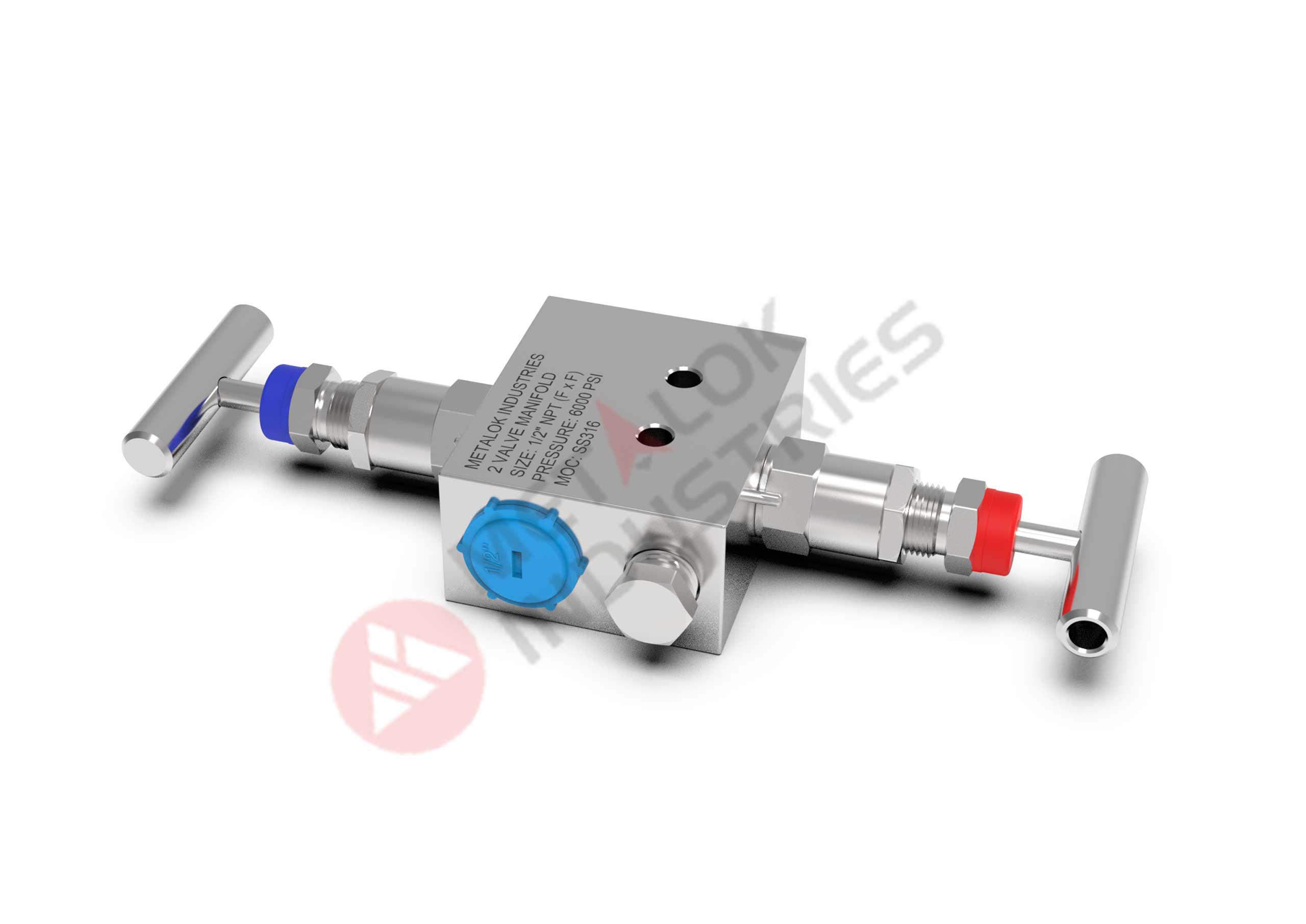

2 Way Manifold Valves – R2, Type 1

The 2 Way Manifold Valve – R2, Type 1 is a precision-engineered valve designed.

2 Way Manifold Valves – R2 Series (Type 2, Type 3, Type 4)

The 2 Way Manifold Valves – R2 Series are engineered for precise pressure control.

2 Way Manifold Valves – R2, Type 2

The R2, Type 2 features a T-pattern design, making it ideal for remote mounting.

2 Way Manifold Valves – R2, Type 3

The R2, Type 3 is a 90-degree angled manifold valve, offering side-mounted installation.

2 Way Manifold Valves – R2, Type 4

The R2, Type 4 is a block-and-bleed manifold valve with an integrated venting system.

2 Way Manifold Valves – R2, Type 5

The 2 Way Manifold Valve – R2, Type 5 is designed for high-pressure instrumentation.

2 Way Manifold Valves – R2, Type 6

The 2 Way Manifold Valve – R2, Type 6 is designed for high-pressure instrumentation .

2 Way Manifold Valve – T2, Type 7 (Direct Mounting)

The 2 Way Manifold Valve – T2, Type 7 is specifically designed for direct mounting.

2 Way Manifold Valve – T2, Type 8 (Direct Mounting)

The 2 Way Manifold Valve – T2, Type 8 is a direct-mounting manifold designed for seamless .

2 Way Manifold Valve – R2, Type 9

The 2 Way Manifold Valve – R2, Type 9 is designed for high-pressure instrumentation.

3 Way Manifold Valve – R3, Type 1

The 3 Way Manifold Valve – R3, Type 1 is engineered for efficient pressure isolation.

3 Way Manifold Valve – R3, Type 2 (Direct Mounting)

The 3 Way Manifold Valve – R3, Type 2 is a direct-mounting manifold designed.

3 Way Manifold Valve – T3, Type 3 (Direct Mounting)

The 3 Way Manifold Valve – T3, Type 3 is designed for direct mounting onto differential .

3 Way Manifold Valve – H3, Type 4 (Direct Mounting)

The 3 Way Manifold Valve – H3, Type 4 is a direct-mounting manifold designed for precise.

5 Way Manifold Valve – R5, Type

The 5 Way Manifold Valve – R5, Type is designed for precise pressure control, isolation.

5 Way Manifold Valve – R5, Type 2 (Direct Mounting)

The 5 Way Manifold Valve – R5, Type 2 is a direct-mounting manifold designed.

5 Way Manifold Valve – R5, Type 3 (Direct Mounting)

The 5 Way Manifold Valve – R5, Type 3 is a direct-mounting manifold designed.

5 Way Manifold Valve – R5, Type 4 (Coplanar Mounting)

The 5 Way Manifold Valve – R5, Type 4 is designed for coplanar mounting.

5 Way Manifold Valve – T5, Type 5 (Direct Mounting)

The 5 Way Manifold Valve – T5, Type 5 is a direct-mounting manifold.

5 Way Manifold Valve – H5, Type 6 (Direct Mounting)

The 5 Way Manifold Valve – H5, Type 6 is a direct-mounting manifold.